No Soldering Required: Explore Alternatives for Building Your Arduino Car

If you prefer to avoid soldering for your Arduino car building project, there are several alternative methods to connect components without using solder. Here are a few options:

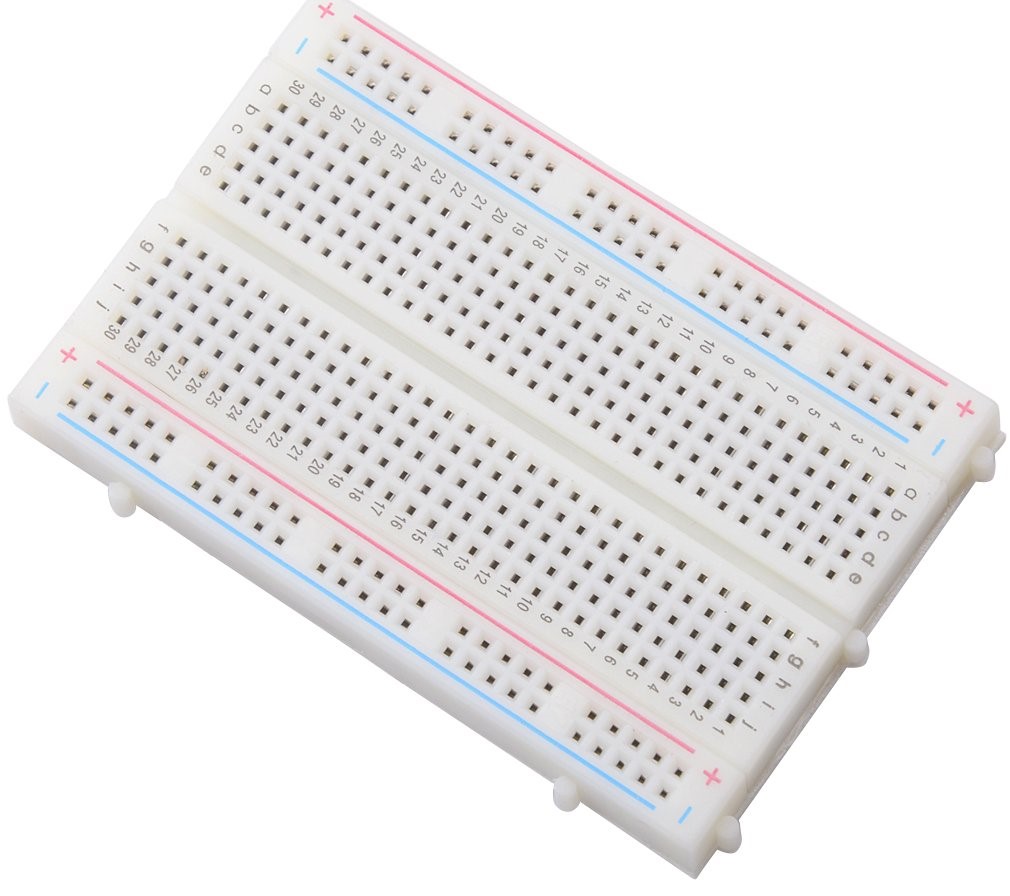

Breadboard

A breadboard is a commonly used tool for prototyping electronic circuits without soldering. It has a grid of holes that allow you to insert and connect components using jumper wires. Breadboards provide a convenient way to quickly assemble and modify circuits. You can place your Arduino board and other components on the breadboard, connecting them using jumper wires.

Breadboards are essential tools in the world of electronics and prototyping. They provide a convenient and reusable platform for designing and testing electronic circuits without the need for soldering. Whether you're a beginner learning the basics of electronics or an experienced engineer working on complex projects, breadboards offer a versatile and user-friendly solution.

A breadboard typically consists of a rectangular plastic board with numerous holes or sockets arranged in a grid pattern. These holes are connected internally in specific patterns, allowing you to easily connect and disconnect electronic components such as resistors, capacitors, LEDs, integrated circuits, and more. The connections are made using metal clips or springs that securely hold the components in place, ensuring a reliable electrical connection.

The primary advantage of using a breadboard is its ability to facilitate rapid prototyping and experimentation. With a breadboard, you can quickly assemble and modify circuits by simply inserting and rearranging components. This flexibility enables you to test different configurations, troubleshoot issues, and refine your design without the need for permanent soldering, which can be time-consuming and irreversible.

Breadboards are particularly beneficial for educational purposes, enabling students and hobbyists to explore electronics and gain hands-on experience. They allow beginners to learn about basic circuitry concepts and understand the connections between components. Breadboards also serve as a safe environment for experimentation, as they eliminate the risk of accidental short circuits or component damage due to improper soldering techniques.

Another advantage of breadboards is their reusability. Unlike soldered circuits, where components are permanently fixed in place, breadboards allow you to disassemble and reuse the components for other projects. This feature makes breadboards cost-effective and environmentally friendly, as you can minimize waste and maximize the utility of your electronic components.

It's important to note that while breadboards are excellent tools for prototyping and learning, they have some limitations. They are primarily designed for low-power circuits and may not be suitable for high-frequency applications or circuits with precise timing requirements. Additionally, the connections on breadboards may introduce additional resistance, capacitance, and inductance, which can affect circuit performance. Therefore, for more advanced or production-grade projects, it's often necessary to transition from a breadboard to a custom PCB (Printed Circuit Board) design.

Breadboards are indispensable tools for electronics enthusiasts, students, and professionals alike. They provide a practical and user-friendly platform for designing, testing, and iterating electronic circuits without the need for soldering. By offering flexibility, reusability, and a safe environment for experimentation, breadboards empower individuals to explore the fascinating world of electronics and bring their ideas to life.

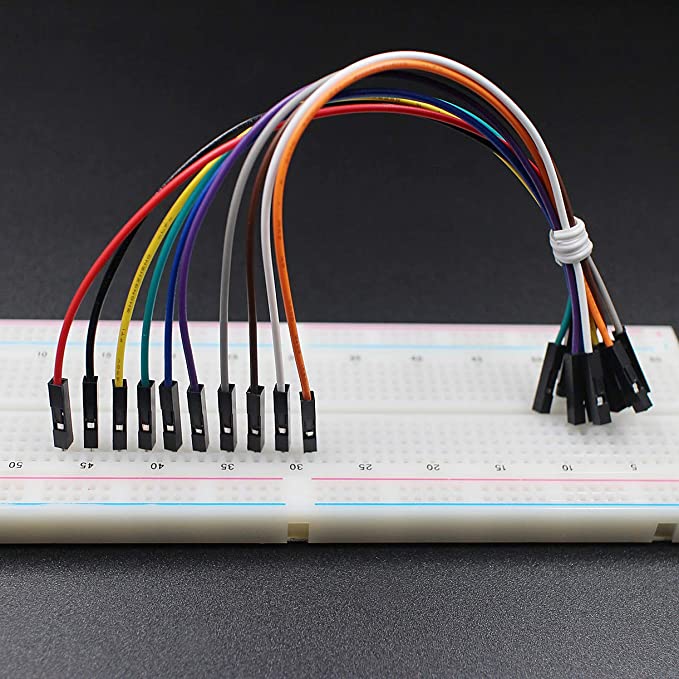

Jumper Wires

Jumper wires are pre-formed wires with connector pins at each end. They allow you to make temporary connections between components. You can use male-to-male jumper wires to connect pins on the Arduino board to the breadboard or to directly connect components together.

Jumper wires can play a vital role in the context of building an Arduino car, as they provide the essential connections between various electronic components, such as motors, sensors, and the Arduino board itself. These wires serve as the conduits for transmitting signals and power, allowing the car to function as intended.

Jumper wires are typically made of insulated copper conductors with male or female connectors at each end. The male connectors consist of metal pins that can be inserted into the female connectors, forming a secure electrical connection. The insulation surrounding the copper wires ensures that the signals do not interfere with each other and minimizes the risk of short circuits.

When building an Arduino car, jumper wires serve several purposes. Firstly, they establish connections between the Arduino board and the motors. By attaching jumper wires from the appropriate pins on the Arduino to the motor driver module, you can control the speed and direction of the motors, enabling the car to move forward, backward, and turn.

In addition to motor connections, jumper wires are used to link various sensors to the Arduino board. For example, distance sensors like ultrasonic sensors or infrared sensors can be connected to the Arduino using jumper wires. These sensors provide input to the Arduino, allowing the car to detect obstacles, avoid collisions, or follow a specific path.

Jumper wires are also essential for connecting other electronic components, such as LEDs, buzzers, and switches. By establishing the appropriate connections using jumper wires, you can control the car's visual and auditory indicators, as well as incorporate user interaction through switches or buttons.

The flexibility and versatility of jumper wires make them invaluable during the Arduino car building process. They enable easy and temporary connections, allowing you to quickly prototype and test different configurations. If adjustments or modifications are required, jumper wires can be easily rearranged or replaced without the need for soldering or permanent modifications to the components.

Furthermore, jumper wires are available in various lengths, colors, and connector types, providing flexibility in managing the wiring of your Arduino car project. Color-coded wires can help you organize and identify different signal types or components, making troubleshooting and maintenance more straightforward.

Jumper wires are essential components when building an Arduino car without soldering. They provide the necessary connections between the Arduino board, motors, sensors, and other electronic components. Their flexibility, ease of use, and temporary nature make them ideal for prototyping, testing, and iterating your car's design. By using jumper wires effectively, you can create a reliable and functional Arduino car that responds to its environment and performs the desired tasks.

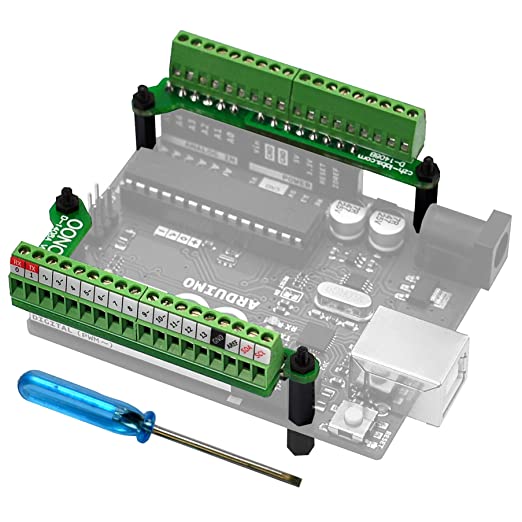

Terminal Blocks

Terminal blocks are connectors that provide screw terminals for secure and removable connections. They allow you to connect wires or components by tightening the screws, creating a reliable electrical connection. You can find terminal blocks in various sizes and configurations, suitable for different wire gauges and component connections.

Terminal blocks are versatile and practical components that serve as an alternative to soldering when it comes to making electrical connections. They are widely used in various applications, including electronics, industrial automation, building wiring, and prototyping. Terminal blocks provide a convenient and reliable way to connect and disconnect wires without the need for soldering or specialized tools.

A terminal block typically consists of a plastic or metal body with multiple screw terminals arranged in a row. Each terminal features a metal clamping mechanism, often in the form of a screw or spring, which securely holds the wire in place. The terminal block body provides insulation and housing for the terminals, ensuring safety and preventing accidental contact.

One of the primary advantages of terminal blocks is their ease of use. Unlike soldering, which requires skill and specialized equipment, terminal blocks allow for quick and tool-free wire connections. You can simply insert the stripped end of a wire into the terminal opening and tighten the screw or engage the spring mechanism to establish a secure electrical connection. This feature makes terminal blocks ideal for situations that require frequent disconnection or reconfiguration, as they allow for easy and reliable adjustments.

Terminal blocks also offer flexibility in wire sizes and types. They can accommodate a wide range of wire gauges, from thin signal wires to thicker power cables. This versatility enables you to connect various types of wires, such as solid, stranded, or multi-conductor cables, without the need for additional adapters or connectors. Moreover, terminal blocks often feature clear markings or color-coding for different terminal positions, facilitating proper wire routing and organization.

Another advantage of terminal blocks is their ability to handle higher current and voltage levels. Compared to soldered connections, which may have limitations due to the type of solder or joint quality, terminal blocks provide a robust and reliable solution for conducting higher power. They can effectively handle currents ranging from a few amperes to several tens or hundreds of amperes, depending on the specific terminal block model and design.

Terminal blocks also offer the advantage of modularity. They can be mounted on DIN rails or PCBs, allowing for easy integration into larger systems or equipment. This modular approach simplifies installation, maintenance, and future upgrades or expansions, as individual terminal blocks can be added or removed as needed.

Furthermore, terminal blocks enhance safety by providing insulation and isolation between wires. The plastic or non-conductive housing of the terminal block prevents accidental contact with live wires, reducing the risk of electrical shock or short circuits. Some terminal blocks even feature additional safety features like finger-proof designs or protective covers, further improving user safety and system reliability.

In summary, terminal blocks are versatile alternatives to soldering that provide convenient and reliable wire connections. Their ease of use, flexibility in wire sizes, ability to handle higher currents, modularity, and safety features make them suitable for a wide range of applications. Whether in electronics prototyping, industrial automation, or building wiring, terminal blocks offer an efficient solution for establishing secure and removable electrical connections.

Header Pins and Female Headers

Header pins and female headers are commonly used for connecting Arduino shields or breakout boards to the main Arduino board. Header pins are inserted into the Arduino board's digital or analog input/output pins, while female headers are attached to the shields or breakout boards. They provide a secure and detachable connection, allowing you to easily connect and disconnect components.

Header pins and female headers are commonly used components that provide an alternative to soldering when establishing connections between electronic modules or boards. They are widely used in applications such as prototyping, circuit board assembly, and interconnecting electronic modules.

Header pins, also known as male headers, are typically comprised of a row of metal pins attached to a plastic housing. These pins are designed to be inserted into corresponding female headers or receptacles, creating a secure electrical connection. The pins are often square or round in shape, ensuring proper alignment and preventing rotation when inserted into the female headers.

Female headers, on the other hand, consist of a plastic housing with receptacles that accept the male header pins. These receptacles are designed to grip and hold the pins firmly in place, establishing a reliable electrical connection. Female headers typically have a single or multiple rows of receptacles, corresponding to the arrangement of pins on the male header.

One of the primary advantages of header pins and female headers is their ease of use. They offer a simple and tool-free method for connecting and disconnecting electronic modules or boards. By inserting the male header pins into the female headers, you can establish a temporary or semi-permanent connection without the need for soldering or specialized tools. This feature is particularly beneficial during prototyping or testing phases when frequent adjustments or modifications are necessary.

Header pins and female headers provide flexibility in terms of connectivity options. They allow for easy interconnection between various electronic modules or boards, such as microcontrollers, sensors, displays, or expansion boards. By using headers, you can create modular systems where individual components can be easily replaced or upgraded without the need for soldering or de-soldering. This modular approach simplifies maintenance, troubleshooting, and future system expansion.

Moreover, header pins and female headers offer a reliable and mechanically secure connection. The friction fit between the male pins and female receptacles ensures a stable and robust electrical connection. This is particularly important in applications where vibration or movement is a concern, as the headers provide a secure connection that resists disconnection due to external forces.

Another advantage is the reusability of header pins and female headers. Unlike soldered connections, which are permanent, headers allow for repeated connection and disconnection without damage to the components. This reusability is advantageous when working on multiple iterations or when components need to be reused in different projects.

Header pins and female headers are available in various sizes, pitches, and configurations to accommodate different applications and specific requirements. They can be easily mounted on circuit boards using through-hole or surface-mount techniques. Additionally, they often feature polarizing keys or notches that ensure correct alignment and prevent reverse insertion, further enhancing their usability and reliability.

In summary, header pins and female headers provide a convenient alternative to soldering for establishing connections between electronic modules or boards. Their ease of use, flexibility, reliability, and reusability make them popular choices in prototyping, circuit board assembly, and modular systems. By using headers, you can quickly and securely connect components, enabling efficient testing, maintenance, and system expansion without the need for soldering or permanent connections.

Terminal Crimps

Terminal crimps are small metal connectors that can be crimped onto wires. They provide a removable connection and can be used with screw terminals or connectors designed for crimping. This method is particularly useful for connecting wires to motors, sensors, or other components.

Terminal crimps, also known as crimp connectors or wire crimps, offer an effective alternative to soldering when it comes to making secure and reliable electrical connections. They are widely used in industries such as automotive, aerospace, telecommunications, and electronics manufacturing, providing a convenient and efficient method for joining wires and cables.

Terminal crimps consist of a metal terminal and a plastic or metal insulator. The terminal is designed to securely grip the wire or cable, while the insulator provides electrical insulation and strain relief. The terminal typically has a barrel or sleeve shape, with a crimping section that holds the wire firmly in place. The insulator covers and protects the terminal, preventing accidental contact and ensuring a safe and reliable connection.

The primary advantage of terminal crimps is the ease and speed with which they can be applied. Crimping requires specialized tools such as crimping pliers or crimping machines, which apply pressure to the terminal, deforming it around the wire. This creates a strong mechanical bond between the terminal and the wire, resulting in a secure and gas-tight connection. Compared to soldering, crimping is generally faster and does not require the use of heat or flux.

Terminal crimps offer excellent electrical conductivity and low resistance. When properly crimped, the metal terminal forms a solid and gas-tight connection with the wire, ensuring minimal resistance to the flow of current. This is crucial for maintaining signal integrity, especially in applications that require high data rates or precise electrical measurements. Additionally, crimped connections are resistant to vibration and mechanical stress, providing long-lasting reliability in demanding environments.

Another advantage of terminal crimps is their versatility. They can accommodate a wide range of wire sizes and types, from thin gauge wires to thick power cables. Various terminal designs, such as butt connectors, spade connectors, ring terminals, and pin terminals, are available to suit different application requirements. This flexibility allows for the connection of wires of different gauges, as well as the integration of wires into larger electrical systems or equipment.

Terminal crimps also offer the advantage of reusability. Unlike soldered connections, which are permanent and difficult to modify or undo, crimped connections can be easily disassembled and re-crimped if necessary. This feature is particularly beneficial in situations where wiring changes or upgrades are anticipated, as it allows for easy reconfiguration without the need for additional materials or equipment.

Furthermore, terminal crimps provide a visually inspectable connection. Unlike soldered joints, which are hidden within the joint, crimped connections can be visually inspected for quality assurance. Properly crimped terminals exhibit a uniform and tight crimp around the wire, ensuring a reliable connection. This visual inspection capability simplifies quality control processes and enhances the overall reliability of electrical installations.

In summary, terminal crimps offer a practical and efficient alternative to soldering for making secure and reliable electrical connections. Their ease of use, excellent conductivity, versatility, reusability, and visual inspectability make them valuable components in various industries. By utilizing terminal crimps, you can achieve robust and high-performance electrical connections without the need for soldering, enabling efficient and cost-effective assembly and maintenance of electrical systems.

It's important to note that while these alternatives can be effective for prototyping and temporary connections, soldering is generally recommended for permanent and reliable connections. Soldering provides a stronger and more secure electrical connection, especially for projects that may experience movement, vibration, or environmental factors. If you plan to build a more robust and durable Arduino car, it's advisable to consider learning soldering techniques or seeking assistance from someone with soldering experience.

We hope you found this article on Arduino car building without soldering helpful and inspiring for your own projects. If you enjoyed reading it, we encourage you to share it with others who might benefit from this valuable information. Together, let's spread the knowledge and excitement of solder-free Arduino connections!

Unlock the Secrets: Get Your Copy Now!

Discover the ultimate resource for building your very own remote-controlled Arduino-based electronic car. Download the comprehensive PDF file that contains everything you need to know, right at your fingertips.

Get the Book Now!